Christian Jaremenko M. Sc.

Researcher in the Computer Vision (CV) group at the Pattern Recognition Lab of the Friedrich-Alexander-Universität Erlangen-Nürnberg

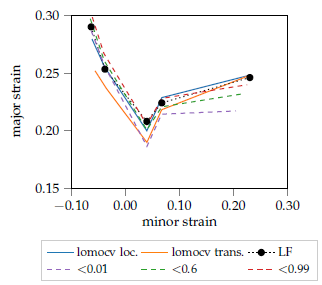

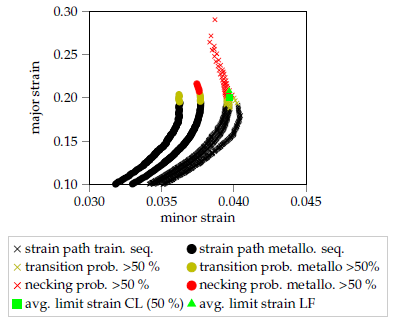

The forming limit curve (FLC) is used to model the onset of sheet metal instability during forming processes e.g. in the area of finite element analysis, and is usually determined by evaluation of strain distributions, derived with optical measurement systems during Nakajima tests. Current methods are time or location dependent and heuristically limit the evaluation area to a small fraction of the available information and additionally show weaknesses in the context of brittle materials without a pronounced necking phase. The aim of this project is the development of an objective and automatic classification method to assess the failure behaviour of sheet metals during forming processes. Consequently, one key aspect of the proposed methods is the definition of a probabilistic FLC to enable an accurate prediction of material behaviours with multiple failure likelihoods e.g. for risk aware process planing, while being time and location independent.

|

|  |  |

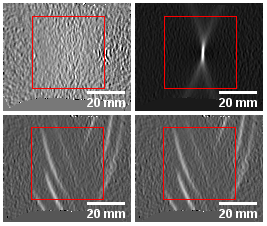

| Different strain distributions. | Forming limit curve and exemplary strain path classification. | |

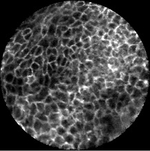

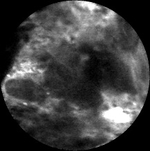

Cancer of the oral cavity is the sixth most common kind of cancer worldwide and has a mortality of above 50 %. The treatment of this disease includes histological analysis of specimen and surgical resection. Confocal laser endomicroscopy is a recently introduced advanced imaging technique which enables microscopic imaging of the mucosa in-vivo. The aim of this project is to automatically classify confocal laser endomicroscopic images according to their disease stage without the need of histological analysis. |  |  |

+49 9131 85 27891

+49 9131 85 27891

+49 9131 85 27270

+49 9131 85 27270